|

|||

智能流體處理產品帶您走得更遠更快

Smart fluid handling to take you forward,faster |

|||

|

高性能聚合物在 HPC 和數據中心應用中的使用 -

塑料在液體冷卻系統中成為可行、可靠的選擇

By

Elizabeth Langer 隨著計算能力和密度(以及它們產生的熱量)的增加,液體冷卻正在成為高性能計算和數據中心應用中首選的熱管理方法。 液體冷卻可以有效地管理熱量,提高能源效率,并且今天的系統足夠強大,可以使用而不必擔心損壞電子設備。 Liquid cooling is emerging as the thermal management approach of choice in high performance computing and data center applications as computing power and densities—and the heat they generate— increase. Liquid cooling manages heat effectively, improves energy efficiency,and today’s systems are sufficiently robust to allow use without fear of damaging electronics.

然而,這并不意味著系統已經完全優化。 快速發展的高性能計算生態系統中的參與者通常處于使用手頭的工具和系統進行部署的位置。 這方面的例子包括: This does not mean systems are fully optimized yet, however. Players in the rapidly evolving high-performance computing ecosystem often have been in the position of deploying with the tools and systems at hand. Examples of this include:

使用空氣冷卻系統,即使它們在高利用率下充分散熱的能力受到挑戰。 Use of air-cooling systems, even as they are challenged in their ability to dissipate heat adequately under high utilization rates.

HPC 和數據中心市場的增長導致整個供應鏈的公司投入研發資金來推進液體冷卻業務。 系統內的組件,包括關鍵的快速斷開裝置,旨在改進形式和功能。 熱工程師可以使用一系列不斷擴大的前沿解決方案、創新方法和新材料來解決液體冷卻方面的緊迫需求。 高性能聚合物就是一個這樣的例子。 The growth of HPC and data center markets has led companies throughout the supply chain to invest R & D dollars to advance liquid cooling operations. Components within the systems, including critical quick disconnects, are targeted for improvement in both form and function. An expanding array of leading edge solutions, innovative approaches and new materials is available to thermal engineers to address urgent needs in liquid cooling. High-performance performance polymers represent one such example.

高性能聚合物改變了對液體冷卻塑料的看法 液體冷卻系統中的聚合物組件之所以有吸引力,有以下幾個原因: 它們重量輕,通常比金屬同類產品便宜,并且不受腐蝕,腐蝕會導致部件無法操作或將碎屑引入流動路徑。 然而,迄今為止使用的許多聚合物面臨的挑戰是它們能夠在不變形、開裂或蠕變的情況下處理高溫和物理壓力源。當發生泄漏時,這些缺點會變得很嚴重,從而導致停機或損壞設備。

HIGH-PERFORMANCE POLYMERS CHANGE THE VIEW OF PLASTICS IN LIQUID COOLING Polymer components in liquid cooling systems are attractive for several reasons: they are lightweight, typically less expensive than metal counterparts, and are impervious to corrosion that can render parts inoperable or introduce debris into flow paths. The challenges with many polymers used to date, however, are their abilities to handle high temperatures and physical stressors without deforming, cracking or creeping.These shortcomings become significant when leaks occur, leading to downtime or damage to equipment.

由于這些缺陷,HPC 制造商和數據中心運營商通常默認使用金屬(不銹鋼或黃銅)快速斷開 (QD) 來滿足其液體冷卻需求。 全金屬或金屬塑料混合選項在承受粗暴處理和長時間保持材料穩定性方面表現良好。 雖然耐用,但全金屬量子點很容易受到腐蝕。 它們的觸感也很熱,為設備的熱插拔帶來了新的意義。 使用它們的系統需要過濾和定期的流體維護,以清除由于腐蝕而產生的潛在碎屑。 As a result of these deficiencies, both HPC manufacturers and data center operators often default to metal (stainless steel or brass) quick disconnects (QDs) for their liquid cooling needs. All-metal or metalplastic hybrid options perform well in terms of withstanding rough handling and maintaining material stability for long periods of time. Though durable, all-metal QDs are vulnerable to corrosion. They’re also hot to the touch bringing new meaning to hot-swapping of equipment. Systems using them require filtration and periodic fluid maintenance to clear out potential debris due to corrosion.

由金屬主體和塑料內部閥門組成的混合連接器可以解決其中的一些挑戰。 這些 QD 具有金屬的強度、耐用性和美觀特性,同時避免了關鍵防溢閥系統中的腐蝕和隨后的性能下降。 Hybrid connectors comprised of metal bodies and plastic interior valves work around some of these challenges. These QDs offer the strength, durability and aesthetic characteristics of metal while avoiding corrosion—and subsequent performance degradation—in critical nonspill valve systems.

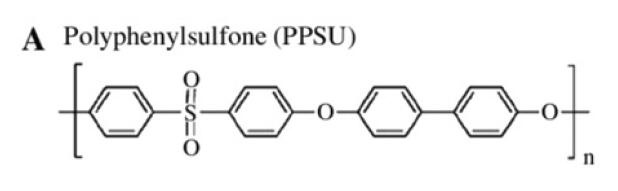

快速接頭的下一個進化發展提供了塑料的優點——重量輕、成本低、防腐蝕和無冷凝——具有與金屬相當的堅固性水平。 與這些能力相關的材料是聚苯砜,PPSU。 The next evolution in QDs delivers the benefits of plastics—light weight, lower cost, anti-corrosion and condensation-free—with a level of robustness on par with metals. The material associated with these capabilities is polyphenylsulfone, PPSU.

PPSU 由通過砜 (SO2) 和醚部分連接的亞苯基芳環組成。 這種獨特的化學成分促進了增強的性能特性,特別適合液體冷卻應用的需求。 鑒于溫水冷卻系統的新興流行,聚合物的耐水解性是一個重要因素。 苯砜和醚基均能抵抗水水解,顯著提高了 PPSU 在水冷卻回路中的整體水解穩定性,進而提高了可靠性。 具有可水解鍵的聚合物在熱水環境中可能存在嚴重性能退化的風險。 機械韌性和抗沖擊性也應該是液體冷卻系統中量子點的關鍵考慮因素; 由于苯醚基團和其他砜(如 PSU 或 PES)中不存在的額外聯苯鍵,PPSU 具有獨特的資質,可提供出色的強度和耐用性以及抗沖擊性。 PPSU is comprised of phenylene-based aromatic rings linked by sulfone (SO2) and ether moieties. This unique chemistry promotes enhanced performance characteristics that are particularly well suited for the demands of liquid cooling applications. Given the emerging prevalence of warm water cooling systems, polymer resistance to hydrolysis is an important factor. Both phenylene sulfone and ether groups being resistant to aqueous hydrolysis significantly increases the overall hydrolytic stability, and in turn reliability, of PPSU in water cooling loops. Polymers with hydrolysable links may be at risk for severe property degradation in hot water environments. Mechanical toughness and impact resistance should also be key onsiderations for QDs in liquid cooling systems; PPSU is uniquely qualified to provide excellent strength and durability as well as impact resistance due to the phenylene ether groups and the additional biphenylene link not present in other sulfones such as PSU or PES.

優異的耐熱性與聚苯砜的高彎曲和拉伸強度、優異的水解穩定性和廣泛的化學相容性相結合。 重復的砜基團增強了聚合物出色的熱氧化穩定性。 長期暴露在廣泛的溫度范圍內是液體冷卻系統中材料選擇的關鍵考慮因素。 可以通過多種方式表征基礎樹脂的熱老化效應,但通常通過報告相對熱指數 (RTI)。 該指數為設計師提供了一個有時限的數據點,在該數據點上,材料仍將保留 50% 的原始屬性。 在 ABS 等商品塑料的 RTI 大約為 50°C 的情況下,PPSU 在連續暴露 100,000 小時后產生的機械 RTI 為 160°C。 Exceptional heat resistance joins polyphenylsulfone’s high flexural and tensile strength, excellent hydrolytic stability and broad chemical compatibility. Repeating sulfone groups reinforce the outstanding thermo-oxidative stability of the polymer. Long-term exposure to a wide range of temperatures is a key consideration of materials selection in liquid cooling systems. Thermal aging effects can be characterized for base resins in a variety of ways, but commonly by reporting a Relative Thermal Index (RTI). This index gives designers a timebound data point at which the material will still have retained 50% of its original properties. Where a commodity plastic such as ABS may have an approximate RTI of 50°C, PPSU yields a mechanical RTI of 160°C after 100,000 hours of continuous exposure.

在為液體冷卻應用指定快速斷開連接時,熱力工程師和數據中心運營商擁有一個新的、強大且可靠的選項:PPSU QD。 在尋求防腐和耐用、可靠的性能時,應考慮 PPSU QD。 CPC 的 PLQ2 系列提供了這些性能要求以及: 佳流速; 高流量/低壓降能力; 在壓力下斷開而不泄漏; 低調、符合人體工程學的設計允許單手連接并在狹小空間內輕松安裝; 和一個多瓣密封件,可在長時間連接期間提供冗余保護以防止泄漏和持久的形狀保持。 In specifying quick disconnects for liquid cooling applications, thermal engineers and data center operators possess a new, robust and reliable option: PPSU QDs. PPSU QDs should be considered when seeking anti-corrosion and durable, reliable performance. CPC’s PLQ2 Series delivers these performance requirements along with: optimal flow rates; high-flow/low pressure drop capacity; disconnection under pressure without leaks; a low-profile, ergonomic design allowing one-handed connection and easy installation in tight spaces; and a multilobed seal for redundant protection against leakage and lasting shape retention during extended periods of connection. CPC 提供業界首款 PPSU QD,專為 HPC 和數據中心的液體冷卻應用而設計。 客戶依靠 CPC 工程專業知識來確保他們的產品和系統提供持久、高效、無泄漏和可靠的性能。 憑借包括定制產品在內的廣泛解決方案,CPC 連接器可滿足苛刻應用的要求。 如需更多信息,請訪問:cpcworldwide.com/liquid-cooling。 或聯系

我們的一位熱管理/液體冷卻工程師在:詢問我們的工程師。 CPC offers the industry’s first PPSU QD, purpose-built for liquid cooling use in HPC and data centers. Customers rely on CPC engineering expertise to ensure their products and systems deliver long-lasting, efficient, leak-free and reliable performance. With a broad range of solutions including custom products, CPC connectors handle the requirements of even the most demanding applications. For more information visit: cpcworldwide.com/liquid-cooling. Or contact one of our thermal management/liquid cooling engineers at: Ask Our Engineers.

|

|||

We inspire confidence at every point of connection.

京公網安備11010502019739 |

陜ICP備11000581號-1

| 聯系我們 |

|

加我微信 |

公眾號 |

|

|||